The most of new drugs contain high-potency active pharmaceutical ingredients (APIs). The cytotoxicity of APIs presents a number of challenges, including handling of said ingredients, and the required investment in specialised containment to ensure that employees and their working environment are protected from exposure.

When selecting sealing components for high containment applications, it is essential to consider the potential problems which may arise in the event of a leak or valve seal failure:

- Operator exposure: employees and the general public must be protected from the product;

- Cross-contamination: there is a particular risk for patient safety in relation to the quality of the product in production.

In order to protect equipment operators and decrease the levels of product contamination from microgram to nanogram levels, it has been necessary for the pharmaceutical industry to advance its containment strategies.

There are three containment approaches which are typically utilised:

- Downflow booths and extracted tables

- Isolators and gloveboxes

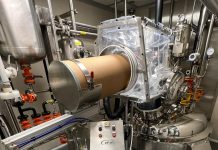

- Split butterfly valves (SBVs)

The addition of a SBV can prove to be a cost-effective solution, particularly where space and existing equipment constraints limit the options available. These valves have demonstrated the ability to meet the containment targets required for handling APIs.

SBVs minimise the amount of airborne particle exposure during the transfer of potent powders from one process step to the next. A fundamental feature of all SBVs is that they consist of two halves which dock together, namely the active “Alpha” unit and the passive “Beta” unit.