Lines for different applications

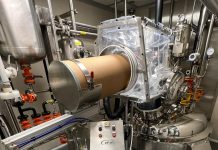

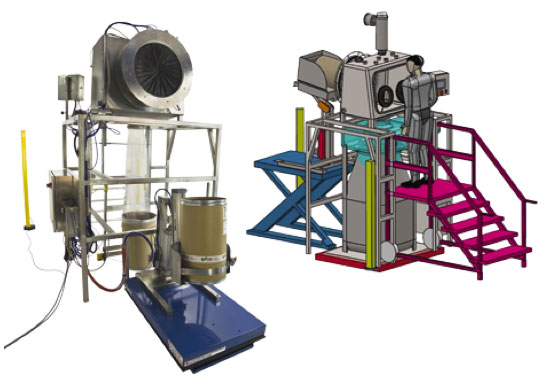

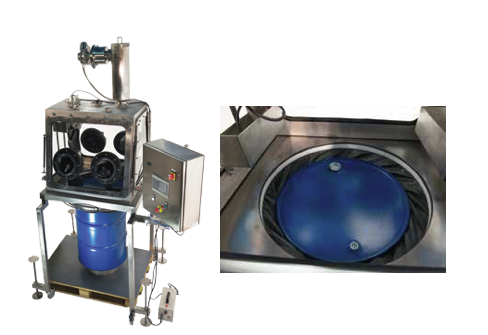

Andrea Pederzini, Containment Engineer at CSV Life Science, recalls the completion of the first installation. “We perceived that we could implement various solutions aimed at handling the containment of drums, above all that, compared to the inflatable seals that guarantee the seal on drums of known diameter, but in the absence of it, they have a real opening between the chamber and the environment outside. Our interface allowed to seal on drums of various diameters”. The first DIT series machine called DUM was built to work in ATEX 2/22 classified area, aimed at containing the load of a dryer in the presence of an anti-acid substance: built in Alloy C22 and conductive materials (graphite filled PTFE and conductive EPDM) was designed in compliance with the regulations of the Machinery Directive. The systems that use this type of interface, developed from 2017 until today, have been various and have led to the creation of a real line of equipment. In particular, we can mention:

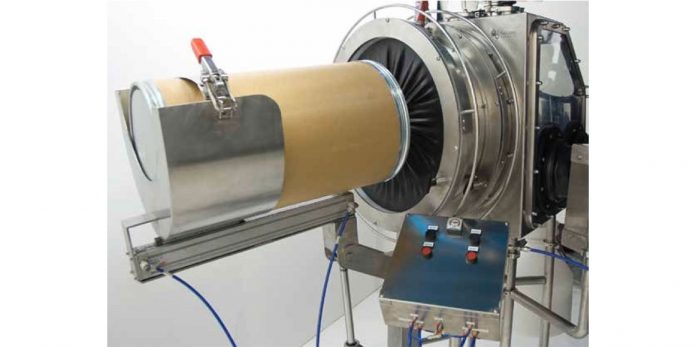

- DRC (Drum Reactor Charging), a reactor charging station

- DILB (Drum Iris Lump Breaker), a lump-breaker with double iris drum load,

- DIIBC (Drum Iris to IBC), a DRUM to BIN system,

- DID (Drum Iris Dispensing), an isolator for dispensing

DIS (Drum Iris Sampling), drum sampling containment system. Another specific production line, dedicated to GMP applications, Dust free or Reach applications, involves the use of a single iris interface. This version provides a telescopic and trailer able system, which varies in coupling to the point of loading (a flange or a hatch), while the rest of the room is universal. This line can also be made of steel and glass, or flexible or rigid plastic, and is not polarized.

R&D: high ranking in Horizon 2020

With this type of project, CSV began to account for the Research & Development activity and to address the issues of subsidized finance and the lost fund. A process of accounting for research was initiated (documented by contracts with external bodies: universities, laboratories or suppliers) and patents (three were deposited to cover this type of application).

In addition, in 2016 and 2017, CSV Life Science participated in the European Horizon2020 call for tenders. The DIT technology has obtained a certificate of excellence from the European Union that certifies the high ranking obtained by the solution proposed in Horizon2020 and therefore won a call for grants accessible only by holders of the Seal of Excellence called Innodriver.

The company has been collaborating with a laboratory in Bologna (PolyCrystalLine) for about ten years, with which has shared the in- vestment in an HPLC line dedicated to the analysis of SMEPAC monito- ring, as well as the development and validation of analytical methods related to real products and different substances of interest (e.g. lactose, mannitol and naproxen).

Vietri comments: “To date we can count on a real database of case histories of monitoring performed on various isolation systems as well as entire departments. The data collected are particularly interesting, because they allow to correlate the batch sizes, transfers, training of the operators and containment systems.”

A Containment System with many Benefits

In conclusion, Drum Iris Techno- logy (DIT) was created to solve problems related to dispensing operations, reactor loading, drum sampling or drum transfers in Bin or other containers. Its use has the advantage of eliminating some problems deriving from the application of the classic Bag In /Bag Out procedure, such as the production of consumables, the costs associated with transferring drums, ergonomic problems to operators and the separation of containers from insulators.

Vietri concludes: “We are convinced that DIT can represent a real innovation in the field of containment and handling, starting from the pharmaceutical field, to which for history and know-how, we turn.

During the past edition of ACHEMA (Frankfurt, 11 – 15 June) and the newt edition of CPhI Worldwide (Madrid, 9 – 11 October), we presented DIT technology applied to a mobile reactor loading station in a fully automatic version. We also participates as speakers at High Purity Day (www.highpurityday.nl) in Vught, Holland, event that highlighted the technological innovations on the European pharmaceutical scene.”